| Thermocouple extension cable and wire |

Thermocouple extension cable and wire

Description

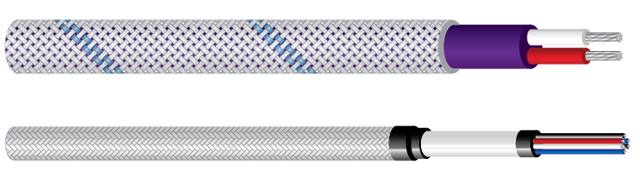

Thermocouple Extension cable and wire which are used in temperature measuring method by Thermocouple, that consists of two dissimilar metals that are joined together at the sensing end. Extension wire uses same materials with thermocouple to extend from thermocouple to measuring equipment.

The insulation on thermocouple extension cable and wire is color coded for identification. For information on usable temperature ranges for the insulation, please find the "Wire Insulation Identification" table. Other tables at this link are also available for information on the metals used in the thermocouple extension cable and wire, insulation color codes, and more.

The insulation on thermocouple extension cable and wire is color coded for identification. For information on usable temperature ranges for the insulation, please find the "Wire Insulation Identification" table. Other tables at this link are also available for information on the metals used in the thermocouple extension cable and wire, insulation color codes, and more.

Certification

UL approved : E314954(PLTC)- FEP, PVC Type

UL approved : E314954(PLTC)- FEP, PVC Type

Application

- Steel industry

- Gas appliance safety

- Thermopile radiation sensors

- Manufacturing

- Power production

- Thermoelectric cooling

- Process plants

- Gas appliance safety

- Thermopile radiation sensors

- Manufacturing

- Power production

- Thermoelectric cooling

- Process plants

Code info.

IEC - KX - F(MD)F - 0.5SQ - 2C

1 2 3 4 5 6 7

1. International standard Code [ DIN / NF /F BS / ANSI / JIS / IEC ]

2. Thermocouple Type

3. Cable Type : X=Extension, C=compensation

4. Insulation Material Identification (Refer above insulation Symbol)

5. Option : S=Shield, MD=Al/mylar+Drain

6. Conductor Size (mm or SQ)

7. No. of Conductor : C=Twist pair , P=Parallel pair

< Option >

1. Copper or SUS brading

2. Al-mylar Tape(screening)

3. Drain Wire(Earthing)

1 2 3 4 5 6 7

1. International standard Code [ DIN / NF /F BS / ANSI / JIS / IEC ]

2. Thermocouple Type

3. Cable Type : X=Extension, C=compensation

4. Insulation Material Identification (Refer above insulation Symbol)

5. Option : S=Shield, MD=Al/mylar+Drain

6. Conductor Size (mm or SQ)

7. No. of Conductor : C=Twist pair , P=Parallel pair

< Option >

1. Copper or SUS brading

2. Al-mylar Tape(screening)

3. Drain Wire(Earthing)

Technical Data

| symbol | Material | temp. Range | Characteristics of Material | ||||||

| Insulation | jacket | Abrasion resistance |

Flexibility | Acid resistance |

Flame Retardant |

Waterproof | Humidity Resistance |

||

| V | PVC | PVC | - 40 ~ 105℃ | ○ | ◎ | ○ | ○ | ○ | ○ |

| K | SILICONE | SILICONE | - 60 ~ 200℃ | ● | ◎ | ● | ● | ○ | ○ |

| F | FEP | FEP | - 80~ 200℃ | ◎ | ○ | ◎ | ◎ | ◎ | ◎ |

| P | PFA | PFA | - 80 ~ 200℃ | ◎ | ○ | ◎ | ◎ | ◎ | ◎ |

| G | Glass Fiber | Glass Fiber | - 20 ~ 400℃ | - | ○ | ◎ | ◎ | - | ● |

Product Range

* Production Type : K, T, E, J, R, S, N, B, W, V

* Manufacturing Standard : IEC, JIS, NF, BSI, DIN, ANSI

* Size : Solid conductor (0.15mm ~ 1.0mm) , Stranded conductor(0.22SQ ~ 2.5SQ)

* Multi-Pair Number : 2 ~ 37 core / 2~37 pair

* Product Error Range : class 1 (Satisfied All International Standard)

* Manufacturing Standard : IEC, JIS, NF, BSI, DIN, ANSI

* Size : Solid conductor (0.15mm ~ 1.0mm) , Stranded conductor(0.22SQ ~ 2.5SQ)

* Multi-Pair Number : 2 ~ 37 core / 2~37 pair

* Product Error Range : class 1 (Satisfied All International Standard)

Products

Industrial Cable

- thermocouple extension

cable and wire

- SIHF/SIF

[Silicone heat resistant cable]

- LK/LKGB

- Instrument and control cable

- Shipboard engine cable [FFCS]

Industrial Cable

- thermocouple extension

cable and wire

- SIHF/SIF

[Silicone heat resistant cable]

- LK/LKGB

- Instrument and control cable

- Shipboard engine cable [FFCS]

Heat Resistant Wire

- Triple insulation wire

- FEP / PFA / ETFE wire

- silicone-glass-wire

- high-temperature-wire

- silicone-rubber-wire

205-16, Gasan digital 1-ro, Geumcheon-gu, Seoul,153-803 TEL 82-2-808-2777 FAX 82-2-803-8380 E-MAIL ycsc@ycsc.co.kr

COPYRIGHT 2007 YOUNG CHANG SILICONE CO., LTD. ALL RIGHTS RESERVED.

COPYRIGHT 2007 YOUNG CHANG SILICONE CO., LTD. ALL RIGHTS RESERVED.